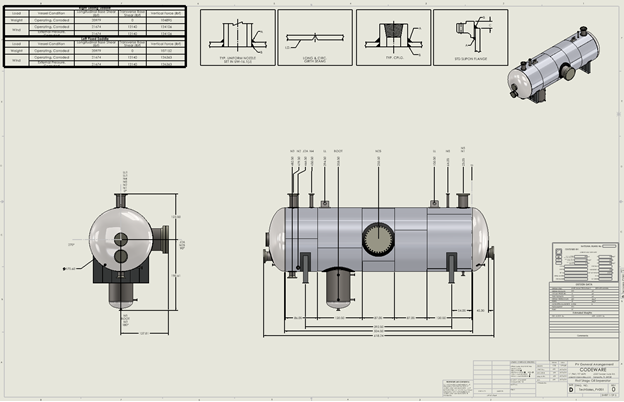

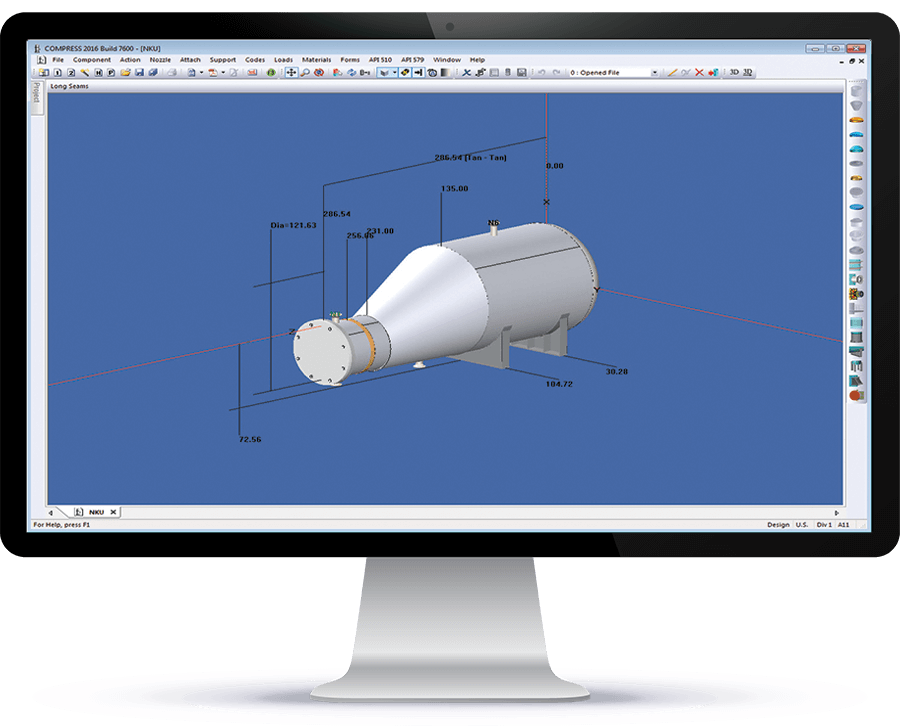

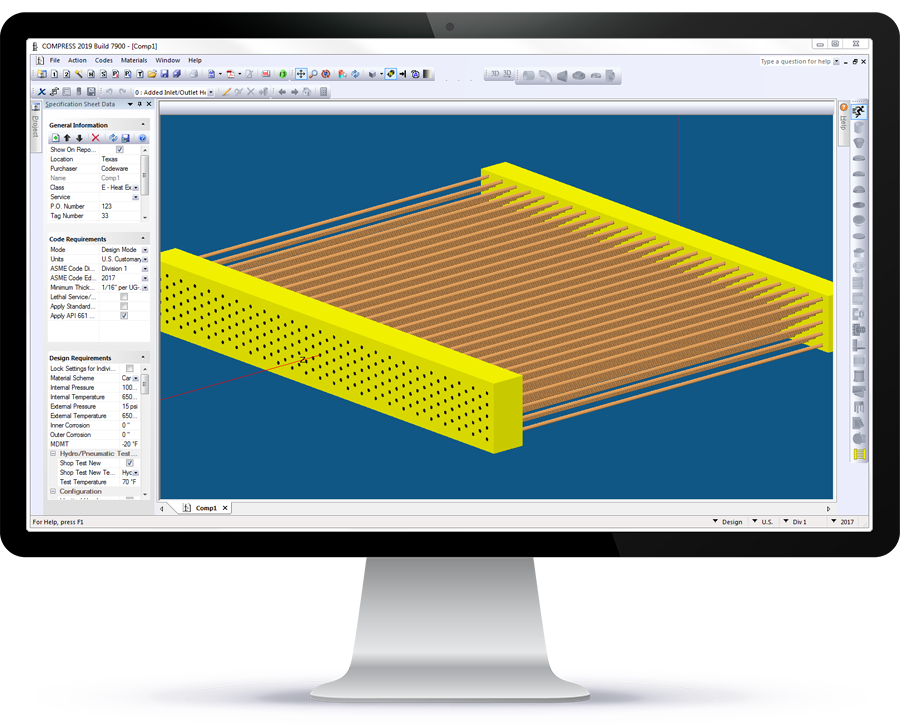

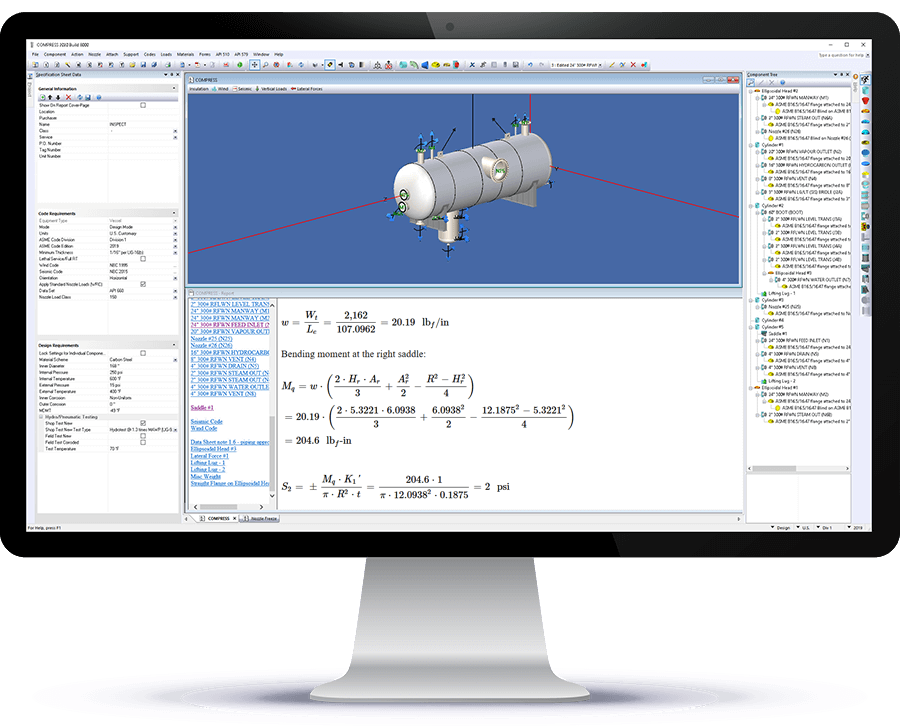

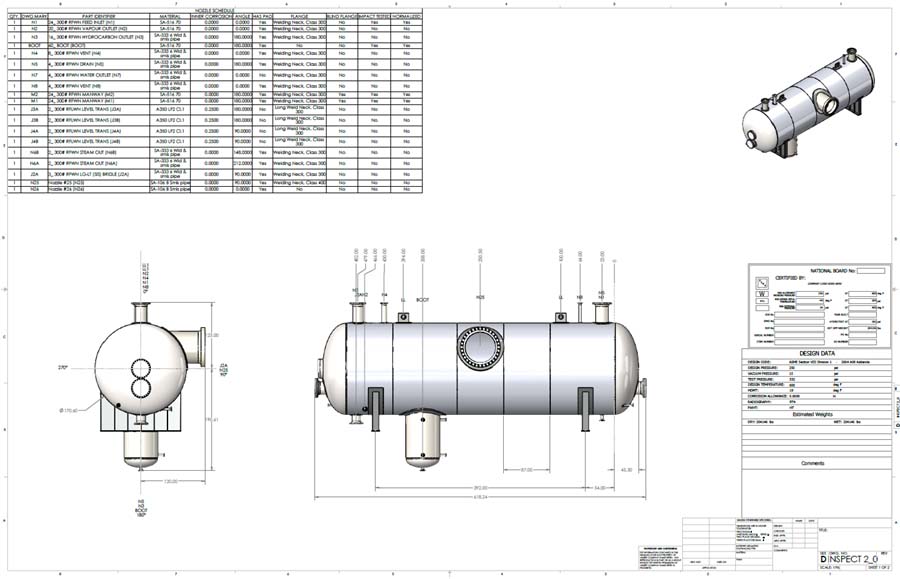

It combines comprehensive ASME calculations with cost estimating solid modeling and automatic drawing generation. The design pressure of any pressurised container is the difference between the internal and external pressure.

Design Calculations J Lowry Llc

Thickness of Circumferential Shells Under Internal Pressure.

. 1 Design Code. Pressure Vessel Calculations and UG-22 Many of the pressure vessel calculations needed to properly design a vessel or exchanger are not by design contained in the ASME VIII BPVC. 11 Design Pressure P 04331rhoh 350 04331 08 1125 mDp 3539 12 13 Hydro Test UG-99b pressure measured at top of vessel rounded up 14 Test Press P 13 MR.

Pressure vessel design to ASME VIII-1 and. COSTER Import files from COMPRESS and create user. This 8ft diameter contact tank or retention vessel keeps water and chlorine in contact for a guaranteed minimum safe amount of time at the maximum possible flow rate.

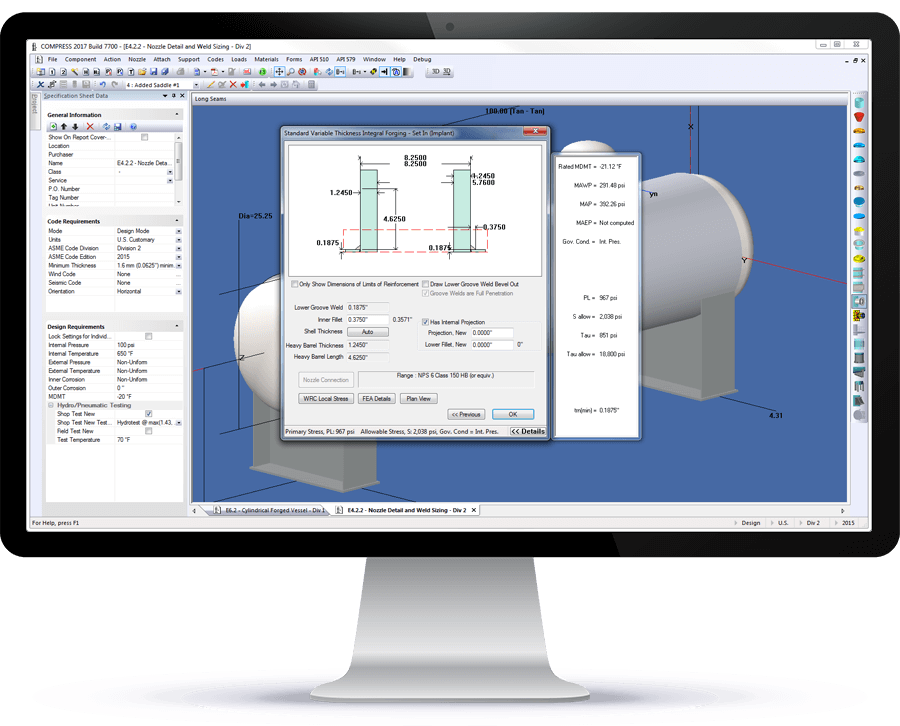

Nominal t Vessel wall nominal thickness Design t Required vessel thickness due to governing loading corrosion Load Internal Circumferential stress due to internal pressure governs. Acceptable types of welded nozzle designs and other connections to pressure vessel shells heads and other geometries. Vessel Wizard The Vessel Wizard speeds pressure vessel design by creating complete pressure vessel models with minimal input.

2010 Add 20112 Process Fluid. Pressure Vessel Nozzle with Repad Design Tool per. Ad Designs Manufactures A Broad Range Of Pressure Vessels Reactors.

If a pressure vessel is exposed to an internal pressure of. In the first example a pad reinforced nozzle on a cylinder is designed per UG-27 UG-37 UG-45 and UCS. The code calculations are performed using Pressure Vessel calculations Heat exchanger COMPRESS for each component of the vessel exchanger to calculate the minimum.

The use of Compress IBC Seismic calculations and using SolidWorks for vessel drawing is discussed. Pressure vessel design to ASME VIII-1 and VIII-2. Platforms Ladders Insulation and Piping.

Standard Custom Designs including Quick-Open ASME available Engineer Support. The COMPRESS Automatic Liquid Level feature saves time and reduces errors by eliminating the need to manually calculate the location specific static head for every nozzle flange shell course and head situated below the normal operating liquid level NLL. The easiest way to design for external pressure is to make the shell thick enough to make the vessel stable with an acceptable factor of safety pass code calculations.

Water3 Operating Pressure. Pressure Vessel Nozzle with Repad Design. COMPRESS saves Engineering hours prevents mistakes and helps shorten equipment delivery times.

External pressure calculation The External pressure calculation divided into two types of calculation due to the vessel s part. Similarly COMPRESS automatically deducts the correct local static head from each components UG-98 MAWP when. We have experience designing thousands of vessels and fittings to multiple codes.

ASME Section VIII Div. Adding attachments directly to a pressure vessel including platforms ladders piping and insulation adds weight and increases the vessels. UG-37 Appendix 1-10 1-7 and div 2.

Pressure Vessel Nozzle Design Spreadsheet Calculator Design calculations for pressure vessel nozzle per. Quote design and fabricate faster and smarter with the leading ASME pressure vessel software. Useful for creating preliminary designs that meet.

Overview - Pressure Vessel Engineering Design Services. If external pressure is requiring vessel sections to get too thick. P Design Pressure internal psi R Inside radius of shell under consideration in S Max.

Pressure Vessel Nozzle Design Spreadsheet Calculator Design calculations for pressure vessel nozzle per. UG-37 Appendix 1-10 1-7 and div 2. 1-The head 2-The shell First.

External pressure design is primarily a function of vessel geometry. Pressure Vessel Design Tools. Hot water heaters and boilers to ASME I and IV.

Use these design tools to size choose materials and determine vessel properties such as weight and volume. A big factor in this calculation is the unsupported length L. See how to design two common ASME pressure vessel components in this video.

Our company also provide pressure vessel engineering. 90 Degree C Max5. We perform ASME calculations for our vessel and piping products in-house.

Pressure Vessel Software For Asme Viii Codeware

Water Softener Vessel Pressure Vessel Engineering

Pressure Vessel Software For Asme Viii Codeware

Pressure Vessel Software For Asme Viii Codeware

Pressure Vessel Software For Asme Viii Codeware

0 comments

Post a Comment